Diamond Burnishing Tools

An economical, easy to use range of tools for producing ultra-smooth surface finishes on turning and boring machines in most ferrous and non-ferrous materials up to 65HRC. There are a range of tools to suit internal and external applications and the burnishing of faces.

- Achieve finishes as low as 0.1µm

- Eliminate grinding and polishing operations

- Use on standard or CNC turning machines

- Simple set-up ideal for low skill levels

- Replaceable natural diamond insert knib

- Available in a range of designs

- Uses existing coolant in machine (always use with coolant)

- Affordable for all workshops

Burnished Finishes on shafts, large bores and faces

The Mollart Diamond Burinishing tool is designed to produce high quality, low micromillimeter burnished finishes on shafts, large bores, and faces. Diamond Burnishing tools can burnish virtually any size stock; from carbon steels, cast iron to alloys, and most ferrous and non-ferrous metals. Since set up and operation is relatively simple, no special operator skills are required. Diamond Burnishing tools are versatile. The tools can be used both large and small diameters, and are ideal for shot production runs. Various models are designed for use in tool post of a manual lathe, automatic, or in CNC equipment.

Applications

- For finishing OD surfaces and faces

- Suitable for materials to 65HRC

- Range of shanks available

- Achieve surface finishes to 0.1Ra

Product Range

Applications

- Achieve finishes as low as 0.20µm

- Eliminate fine boring, grinding and polishing operations

- Simple set-up

- Economical long tool life with carbide roll

- Carbide roll can be refurbished

- Available with a range of metric and imperial shanks

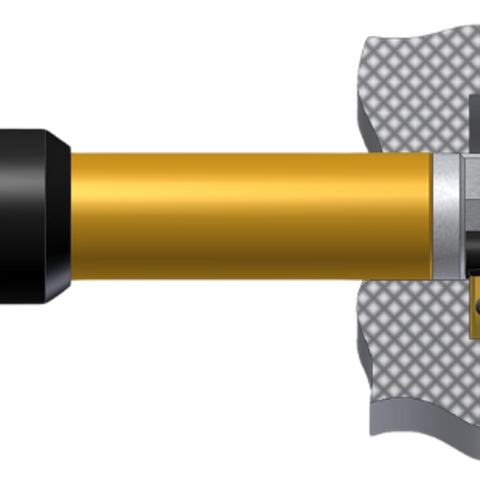

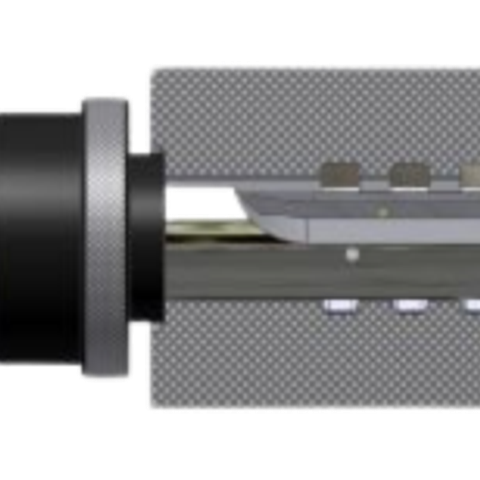

Applications

- Combined skive & burnish tools

- Range Ø60mm to Ø400mm

- Feed rates 3 to 6 mm/rev

- Finish tube bores in a single pass

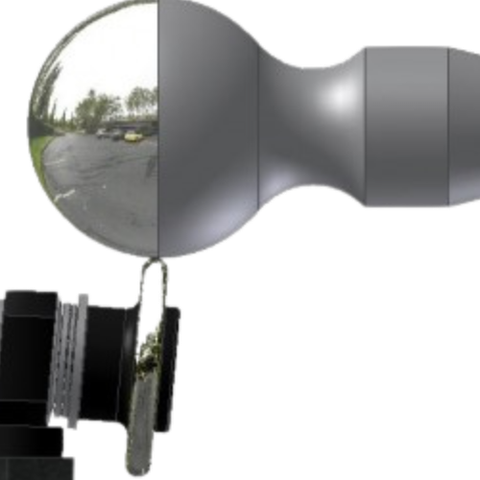

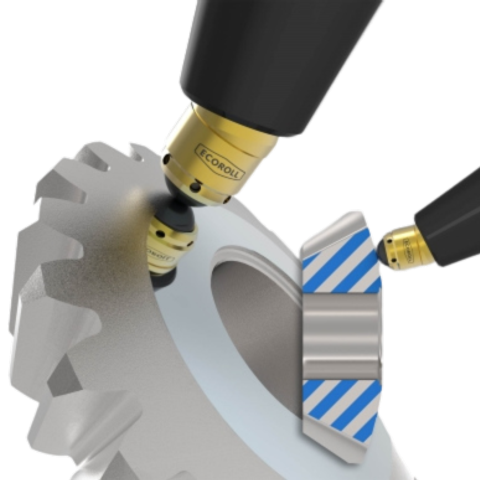

Applications

- Roller burnishing up to 65 HRC and deep rolling

- Increase fatigue strength for internal, external diameters and fillet radii

- Follow complex contours and free-form surfaces

- Range of ball sizes available

- Uses high-pressure oil or air

Applications

- Suitable for bores and shafts

- Remove need for honing, grinding, fine boring

- Finishes down to 0.1Ra

- Improve surface hardness