BTA & Ejector Drills

botek Range

botek manufacture a wide range of BTA single tube and ejector twin tube deep hole drills from

Ø7.76mm through to Ø500mm, and larger as special application tools.

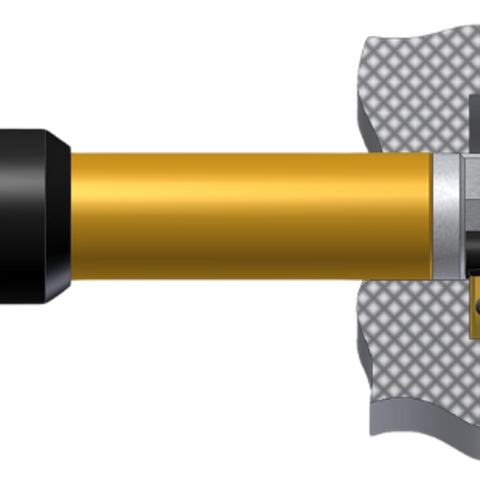

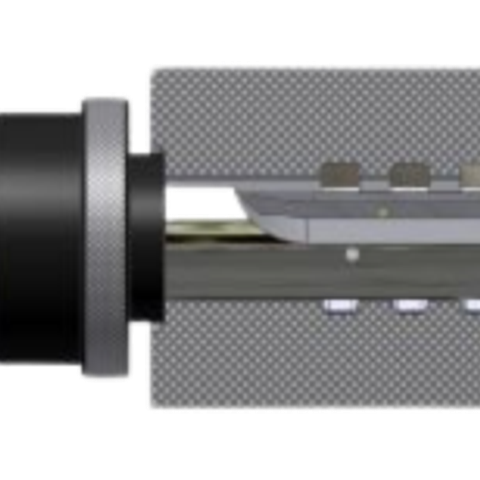

BTA drills are used on dedicated machinery where the coolant is induced through a pressure

head and the chips are then evacuated through the centre of the drill and the drill tube. Tube

dampers are used to support the drill tube and prevent vibration and distortion of the tube, and

work steadies support the work piece if required.

Ejector drills are used on conventional and CNC type machines. They use an inducer to feed coolant between the inner and outer twin tube system with the chips being ejected through the

centre of the inner tube. With CNC machines now utilising high pressure coolant botek are able to offer alternatives to the ejector system.

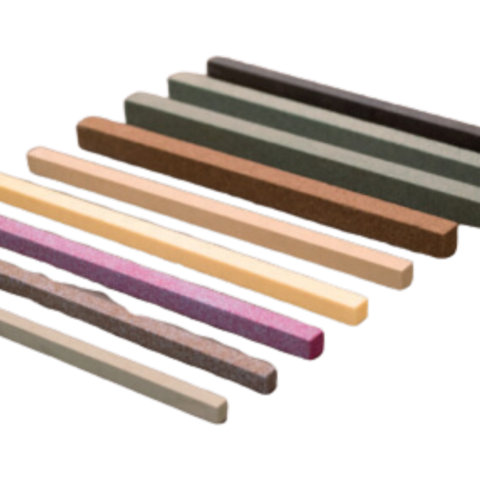

Solid drill heads with brazed carbide inserts

These are available from Ø7.76mm to Ø65mm. These heads can be reground and re-tipped / re-coated but are considered a consumable item and therefore have a limited life. Inserted drill heads are available from Ø15mm upward and allow quick insert changes and on heads above Ø25mm the ability to adjust the cutting diameter. Counterboring heads with indexable inserts are available from Ø28.5mm upward and allow holes to be bored out to larger sizes after solid drilling. As they use less power than solid drill heads, larger diameters can be produced on machines with limited power. Trepanning heads are available from Ø55mm and produce an inner core that can be reused saving material costs.

Special Tools: We can provide customised gundrills to suit your unique applications

Applications

- Brazed drill heads from Ø7.76mm

- Inserted drill heads from Ø18mm

- Counterboring heads from Ø28.5mm

- Drill tubes, pressure heads and coolant inducers available

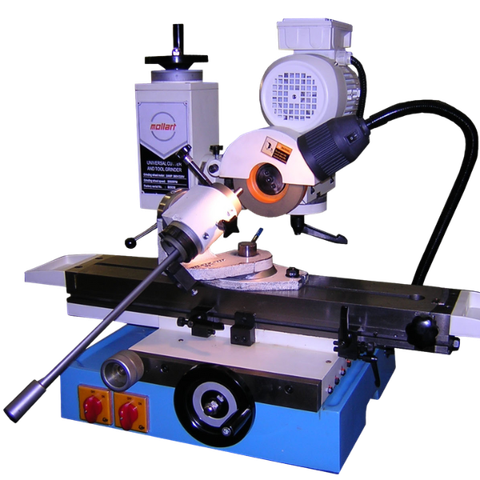

botek's BTA Drilling System

Take a moment to explore the fascinating performance of botek’s BTA drilling system.

botek manufactures BTA drilling, counter boring and trepanning tools for use on the Mollart deep hole drilling machines. Sizes start at Ø18mm and go to Ø400mm for solid drilling with counter boring heads available to Ø800mm. As the exclusive UK agent for botek, Mollart can make and supply tools to meet your exact requirements with a 24-hour service available.

Product Range

Applications

- Brazed BTA drill heads from Ø7.76mm

- Brazed Ejector drill heads from Ø18.40mm

- Drill tubes and coolant inducers available

- Special heads upon request

Applications

- BTA insert drills from Ø15.65mm

- Ejector insert drills from Ø18.40mm

- Counterboring tools from Ø28.50mm

- Trepanning heads from Ø55mm

- 1 & 4-start drill tubes

- Tube drivers, vibration dampers and pressure heads available