BCU Precision Back Chamfering

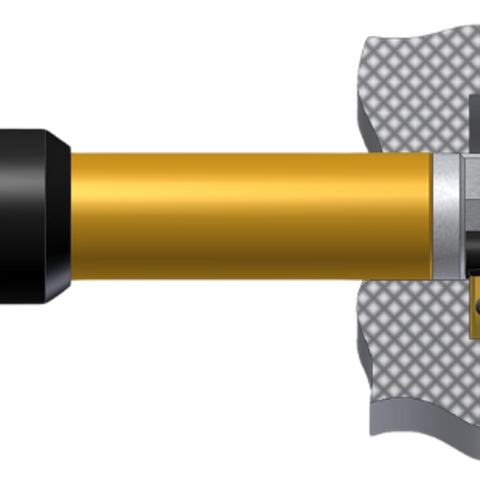

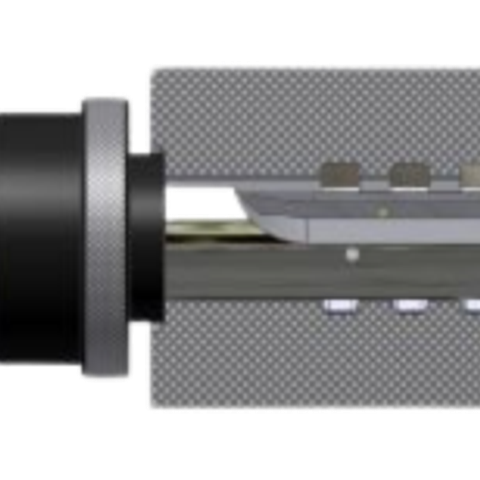

The 'BCU' back chamfer unit is the fast, efficient method for the production of precision back chamfers and back countersinks. The system ensures precise control of the chamfer size and concentricity to the bore.

- Positive back chamfering and deburring of holes

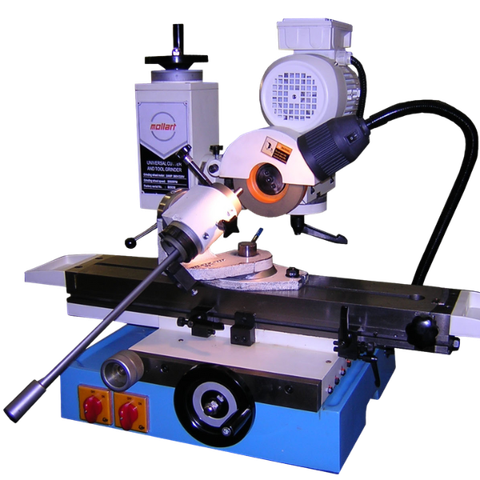

- Suitable for CNC, manual and special purpose machinery

- Total cycle time typically 5 to 6 seconds

- Chamfers produced concentric to bore due to pilot location

- Rigid set-up with cutter mounted within support pilot

- Micro-adjustment of chamfer size using limiting nut or CNC machine control

- Ø10mm shank standard with alternative options available

Applications

- Precision back chamfering

- Angles and blend radii produced

- Chamfer flat and restricted access faces

- Curved faces chamfered >3:1 bore ratio

Fast and Efficient Back Chamfering System

Take a moment to explore the fascinating performance of BCU back chamfering system

The “BCU” back chamfer unit is the fast, efficient method for the production of precision back chamfers and back countersinks and precision deburring of holes. The system ensures precise control of the chamfer size and concentricity to the bore.

BCU Back Chamfering - For Precision Deburring

Product Range

Applications

- Combined front and back deburring of holes from a single side

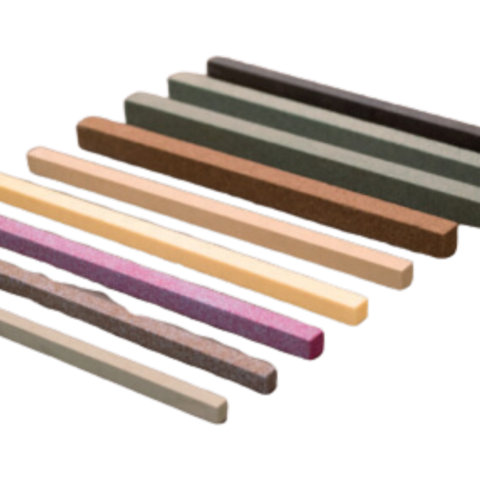

- HSS tools Ø1.0mm – Ø50mm

- Carbide Series from Ø3.0mm

- Combination Drill & Deburr from Ø9.5mm

Applications

- Clothespin style hole deburing tools

- Tools from Ø2mm to Ø25.4mm

- Extended length tools available

- Integral tension adjusting pin above Ø8mm