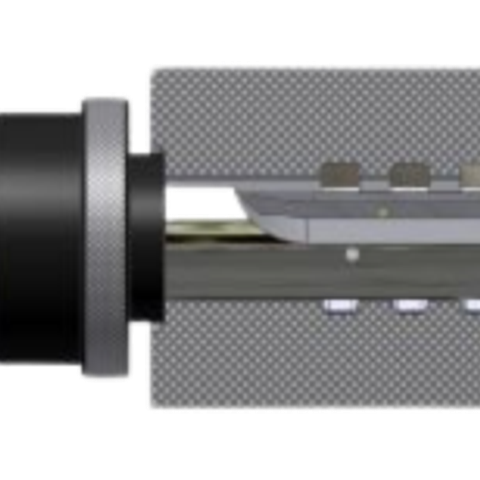

Cone Style Autofacer

Mechanically opened when the cone contacts the machined face of the part or a fixture using the friction drive of the integral cone and clutch mechanism.

The Cone activated Autofacer offers a versatile method for creating back spotfaces, counterbores and chamfers utilising CNC machine tools or special purpose machines.

Tools available from Ø6.35mm (Ø0.250") pilot diameter and are capable of producing features up to 2.2x's the pilot hole diameter.

Applications

- Cone drives in to top face to positively open cutter

- Cutter locked in position by internal clutch mechanism

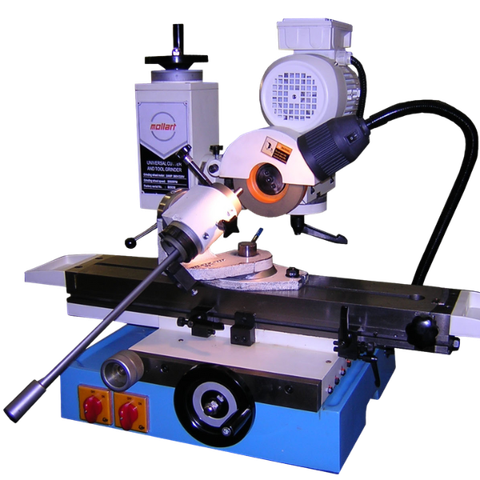

- Ideally suited to production on CNC machinery

- Available from Ø6.35mm pilot hole diameters

Mechanically Opens When the Cone Contacts

Take a moment to explore the fascinating performance of the Steiner Cone Activated Autofacer.

The Autofacer back spot-facing tools allow features to be machined without the need to access the part from behind. The Torque Bar opens the cutter and then holds it in the open position during the cutting process No human intervention, fully automated processing and up to 80% reduction in process cycle times!

Steiner Cone Activated Autofacer

Product Range

Applications

- Utilises an anti-rotation device to activate the blade during spindle reversal

- Ideally suited to high volume production

- Use on CNC machines and transfer lines

- Spot faces > 2.2 x pilot hole Ø possible

Applications

- Rapid rotation of machine spindle opens cutter

- Simple to set up and program

- Ideally suited where part thickness varies

- Internal coolant from pilot Ø15.62mm