Send an enquiry or get a quote

Contact Us

"The Hole Solution from a Single Source Supply"

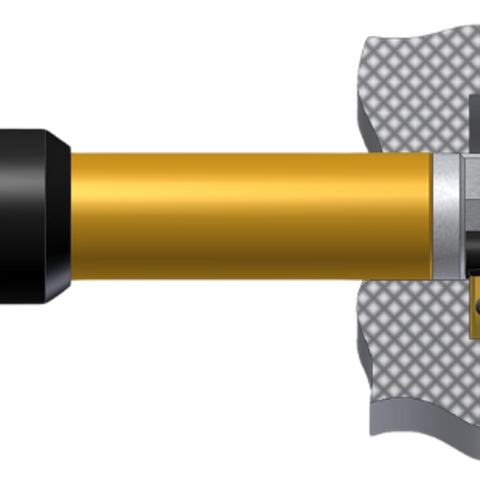

- Botek gundrills Ø0.5mm to Ø100mm

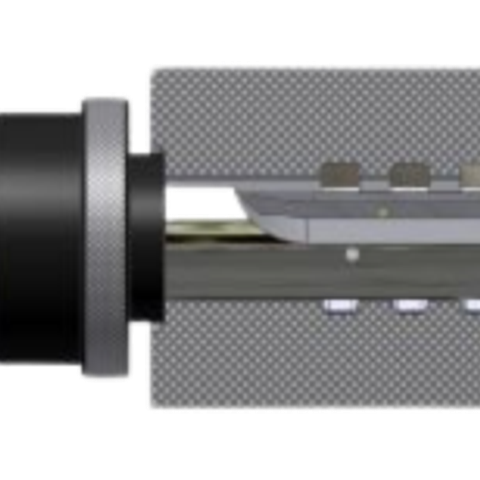

- Botek BTA and ejector drills up to Ø400mm

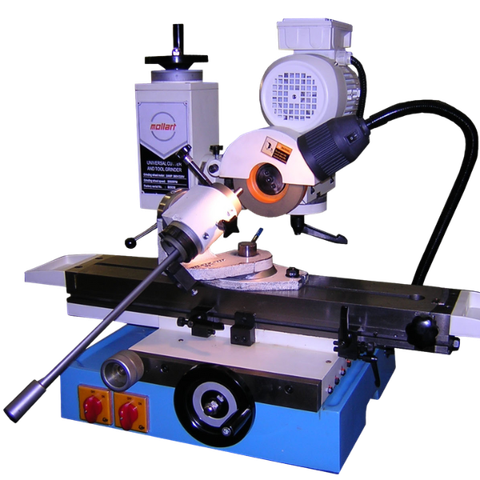

- Gundrill regrind and re-tipping service

- Spray mist gundrill coolant system

- E-Z Burr hole deburring tools from Ø1mm

- Elliott roller burnishing and diamond burnishing

- Autofacer back spot facing and counter boring

- Bencere IRU internal grooving system

- Bencere precision back chamfering

Product Range

Sectors

- Automotive

- Medical

- Oil and Gas

- Construction

- Aerospace

- Pellet food dies

Applications

- Brazed drill heads from Ø7.76mm

- Inserted drill heads from Ø18mm

- Counterboring heads from Ø28.5mm

- Drill tubes, pressure heads and coolant inducers available

Applications

- Ideal for flange holes

- Cross hole deburring

- Precision chamfering for countersunk screws

- Large sheets and boiler plates

- Hydraulic and fluid power

- Automotive industry

- Medical

Applications

- Round bores and shafts

- Integrated in existing machining operations

- Multiple surface capability

- Mirror-like surface finish (0.13 to 0.20 µm)

- Accurate sizing

- Work hardening of surface

- Through or blind holes

- Angled and flat faces possible

Applications

- Bolt head seating faces

- Differential cases - spherical and flat

- Valve seat pocketing

- Gate valves

- Planetary gear carriers

- Gearbox casings

- Landing gear

- Special inserts with chamfer and other forms on request

Applications

- Automotive Piston internal and external gudgeon bore features

- ‘Land face’ machining in hydraulic valve bores

- Single and multiple circlip and ‘O’ ring grooves

Applications

- Holes between Ø5mm and Ø25mm

- Hole depth up to 2,000mm

Applications

- Gundrill Ø Range: 5-25mm Up to 2000mm deep

- Coolant/Air Inducer up to 10 bar with No.4 Morse Taper Fitting.

- Spraymist Unit 84-4020-4PT-M-6-MB complete with Magnetic Base.

Features

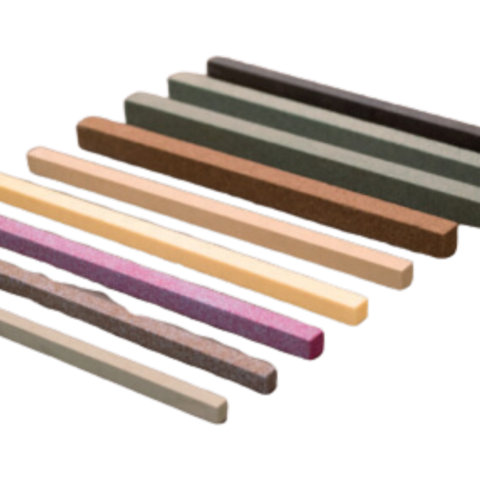

- Abrasive Cross-Sections from .06” and Above and Lengths to 8.0”

- Hybrid Ceramic & Related Products

- Impregnated Fiber Sticks

- Conventional & Custom Mountings