Send an enquiry or get a quote

Contact Us

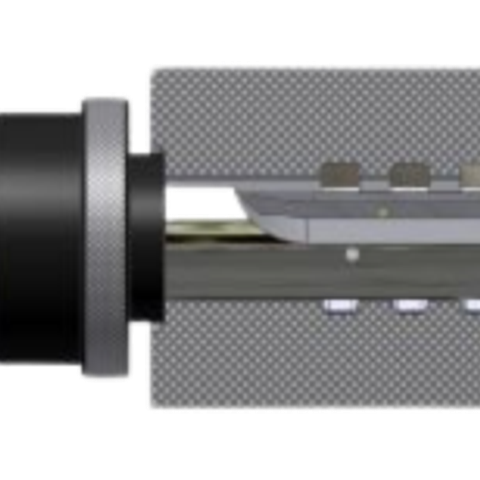

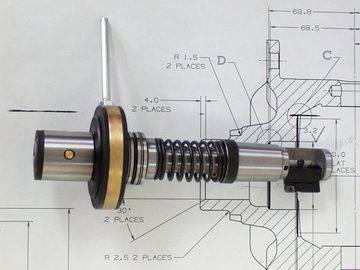

Autofacer Back Spot Facing

Mechanically opened, robust and versatile for creating back spot faces, counterbores, chamfers, spherical cuts or profiled surfaces in CNC machine tools and special purpose machines.

The “Autofacer” tools perform manual or automatic back spotfacing and counterboring operations up to 2.2x’s the pilot bore diameter (greater on larger diameter tools)

- Chip-to-Chip times reduced by as much as 80% over conventional tools

- Eliminates costly second operations and saves time through process improvement

- Carbide tipped, indexable inserts and PCD tips available in a range of grades and coatings

- Internal mechanism ensures the blade opens and closes positively and reliably each and every time

- Tools can perform heavy interrupted cuts smoothly without excessive chatter

- Ø6.35mm (Ø0.250") minimum pilot hole diameter

- Unlimited depth-to-diameter ratio due to the support pilot

- Fast, simple cutter change

- Precision back boring and large diameter tools available

- Short delivery times using standard components

- Robust and versatile

- Back spotface, counterbore, seat pocket machine or chamfer

- Produce spherical or profile spotfaces

- Works on interupted surfaces

Applications

- Bolt head seating faces

- Differential cases - spherical and flat

- Valve seat pocketing

- Gate valves

- Planetary gear carriers

- Gearbox casings

- Landing gear

- Special inserts with chamfer and other forms on request

Eliminate Secondary Operations

Take a moment to explore the fascinating performance of automatic back spot-facing tools.

Producing back spotfaces and back counterbores is made easy using the Autofacer tool. It eliminates secondary operations and removes the need for operator intervention in the machine cycle.

Back Spotfaces and Counterbores Made Easy

Product Range

Applications

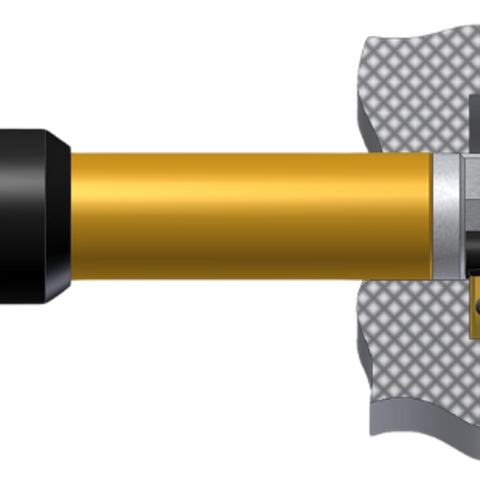

- Utilises an anti-rotation device to activate the blade during spindle reversal

- Ideally suited to high volume production

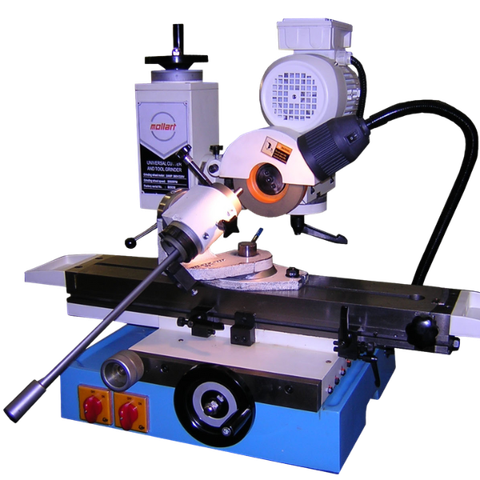

- Use on CNC machines and transfer lines

- Spot faces > 2.2 x pilot hole Ø possible

Applications

- Rapid rotation of machine spindle opens cutter

- Simple to set up and program

- Ideally suited where part thickness varies

- Internal coolant from pilot Ø15.62mm

Applications

- Cone drives in to top face to positively open cutter

- Cutter locked in position by internal clutch mechanism

- Ideally suited to production on CNC machinery

- Available from Ø6.35mm pilot hole diameters