Providing World Leading Deep Hole Drilling Solutions

Mollart Engineering is a world leader in the provision of deep hole drilling, precision subcontract machining and assembly services and the manufacture of cutting tools for the mechanical engineering industry.

Process Driven Solutions

Established in 1929, and with engineering facilities covering approx. 60,000 sq ft across sites in Chessington, Surrey and Resolven, South Wales, Mollart Engineering have built a worldwide reputation for engineering excellence and process driven solutions across a wide sector of industries including Semi-conductor, Oil and Gas, Medical, Automotive, Telecommunications, Defence, Nuclear and Aerospace.

Excellence in engineering

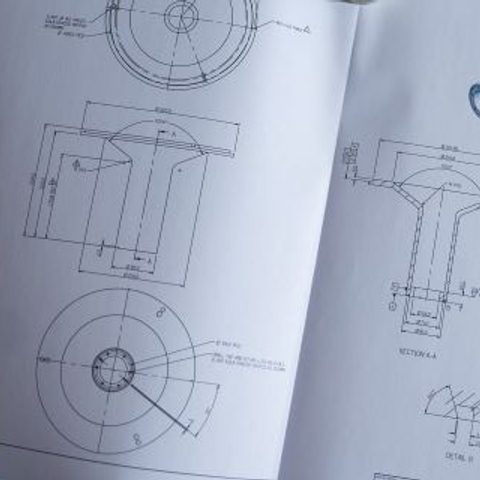

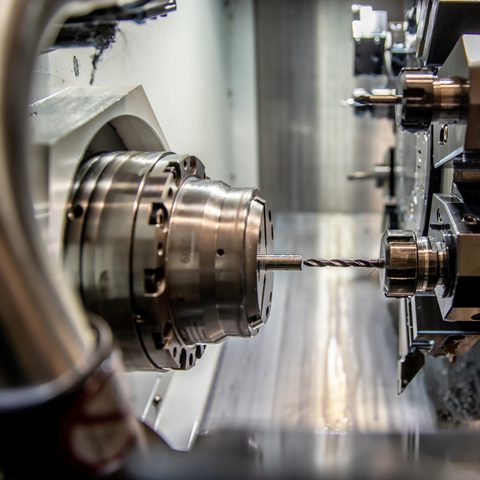

Precision Subcontract Machining Services

Our precision subcontract machining services include turning, milling, boring, honing and gundrilling, enabling totally streamlined project-managed services including assembly and test within an ISO 6 Class 1,000 cleanroom facility. We are also Quality Certified to ISO9001:2015. Our first class machinery and engineering skill set ensure that we are able to provide on time delivery to our customer base ensuring that even the tightest of tolerances are achieved across a variety of materials.

World-leading tooling solutions

Mollart’s world leading tooling solutions include the supply of tooling for hole processing offering gundrills and BTA drills, hole deburring and chamfering, burnishing, back spot facing and internal grooving. Additional tooling solutions such as BTA drills, deburring tools, roller burnishing tools, back spot facing tools, IRU grooving, spray mist systems and abrasive honing stones are also part of the full range of Tooling. A Tooling regrinding and gundrill re-tipping service are also provided.

Meeting the demands of a modern world

Headed by a strong management team and long standing base of skilled employees, which is complimented by an apprenticeship program to raise the next generation of engineers, Mollart Engineering have extensive knowledge, experience and expertise to meet the ever changing engineering demands of a modern world.

View our Broad Range of Subcontract Machining Services

Tooling

Mollart’s world leading tooling solutions include the supply of tooling for hole processing offering gundrills and BTA drills, hole deburring and chamfering, burnishing, back spot facing and internal grooving. Additional tooling solutions such as BTA drills, deburring tools, roller burnishing tools, back spot facing tools, IRU grooving, spray mist systems and abrasive honing stones are also part of the full range of Tooling. A Tooling regrinding and gundrill re-tipping service are also provided.

Mollart's range of deep hole drilling tools

Mollart Training and Apprenticeships

Investing in the Next Generation of Precision Engineers

Headed by a strong management team and skilled precision engineers, the focus of our apprenticeship program is aimed at providing outstanding training and support to the next generation of experienced deep hole drilling engineers. Many of our young engineers stay with us at Mollart where they can use their skills in order to meet the ever-changing engineering demands of a modern world.

Contact apprenticeships@mollart.co.uk for more information