- Deep Hole Drilling Tools

- Gundrills

- BTA & Ejector Drills

- Hole Deburring

- Roller Burnishing

- Autofacer Back Spot Facing

- IRU Grooving

- Spray Mist System

- Service Regrinding & Gundrill Re-tipping

- Abrasive Honing Stones

Sectors

Contact Us

-

-

Chessington

- Deep Hole Drilling & Boring

- 5 Axis Machining

- CNC Gundrilling

- Honing, Turning & Milling

- Manual Deburring and Surface Finishing

- Project Management at Mollart

- Quality Control and Inspection

- Glass Bead Pean for the Energy Sector

- Tig Weld Capability

- Pressure Testing at Mollart

- 3D Printing / Rapid Prototype

- Capabilities at Chessington

-

Chessington

- News

- Mollart Machinery

Reducing Annual Production Costs With The Back Spot Autofacer Tool

Back Spotfacing Case Study

The Customer

A Subcontract heavy equipment manufacturer of medium to large precision-machined components based in the North of England.

The Tooling Challenge

The customer was looking to lower annual production costs in the back spotfacing of over 3,500 holes per year on aluminum cast components within their specialised machining facility.

The Tooling Solution: The Back Spot Autofacer Tool

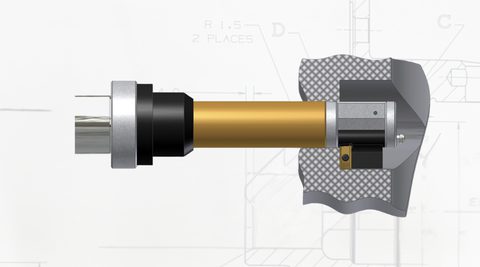

The solution provided to the customer was the introduction of the Back Spot Autofacer Tool, which mechanically opens and is robust and versatile for creating back spot faces, counterbores, chamfers, spherical cuts or profiled surfaces in CNC machine tools and special purpose machines.

Bump Style Activation

By replacing the two-piece tool, which was currently being used by the customer, a bump style activated Autofacer was brought into the process to fully automate the back spotfacing operation.

The production process included the entering of a 1” thick wall in a 0.551” hole with a spotface requirement of 1.063”, which therefore eliminated a secondary operation and operator intervention. This assisted with reducing over-production time and thus internal costs.

The Results

There was significant cost-cutting per hole, with an annualised production time saving of approximately 500 hours. This resulted in major cost savings per annum for the customer. Having a streamlined automated ‘all in one’ process not only reduced costs, it also improved safety. Previously, a machinist would need to manually change and take out a cutter head blade that was no longer needed. Therefore, because the Autofacer tool eliminated this secondary operation, safety concerns were removed from the process.

See our full range of Autofacer tools

Get in Touch

For more information about Back Spot Autofacer Tooling at Mollart Engineering (Chessington), or to discuss a project, please contact us at sales@mollart.co.uk You can also find more contact details below: