Roller Burnishing Tool

Roller burnishing improves surface finish of parts, eliminating processes such as grinding and honing. It is a 'chipless' machining method which cold works the metal without cutting or abrading the surface. It removes no metal but rather compresses, or 'irons out', the peaks of a metal surface into the valleys, generating a dense and uniform surface. Tools can be used on any driven machine spindle with the burnishing process being fast, efficient and cost-effective.

- Improve surface finish - as low as 0.1mm Ra

- Improve surface hardness up to 10%

- Improve dimensional accuracy

- Reduce noise & friction levels

- Improve fatigue life

- Improve corrosion resistance

- Increase production output

- Reduce manufacturing costs

- Low skill levels required

- Environmentally friendly process

- Long tool life

- Low inventory requirements

- Conventional part preparation

Mollart Multi-Burnishing Tools

Our Burnishing Tools are designed for burnishing shafts, faces tapers, contours, at any diameter and IDs greater than 70.0mm

- Boring-Bar style and Indexable turning-holder style designs

- Turning-Holder style available with force gauges

- Tool designs to suit any size or configuration, or any turning machine

- Low surface finishes

- Standard, available off-the-shelf

- Adjustable for optimum burnishing pressure

- Hardened steel or carbide rollers

Applications

- Suitable for bores and shafts

- Remove need for honing, grinding, fine boring

- Finishes down to 0.1Ra

- Improve surface hardness

Outstanding Performance

Take a moment to explore the fascinating performance of Roller Burnish Tools.

Roller burnishing Tools are designed for burnishing shafts, faces tapers, contours, at any diameter and IDs greater than 70.0mm

Roller Burnishing For Improved Surface Finished Parts

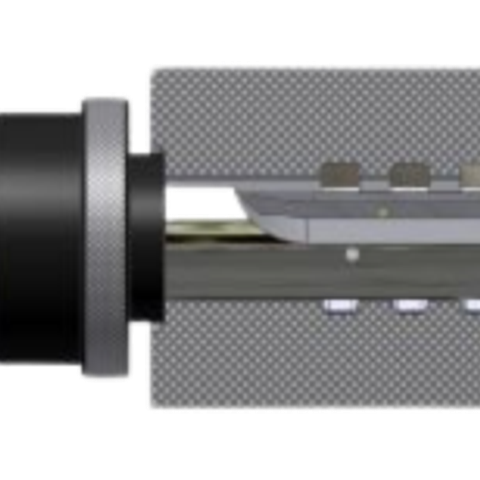

Product Range

Applications

- Achieve finishes as low as 0.20µm

- Eliminate fine boring, grinding and polishing operations

- Simple set-up

- Economical long tool life with carbide roll

- Carbide roll can be refurbished

- Available with a range of metric and imperial shanks

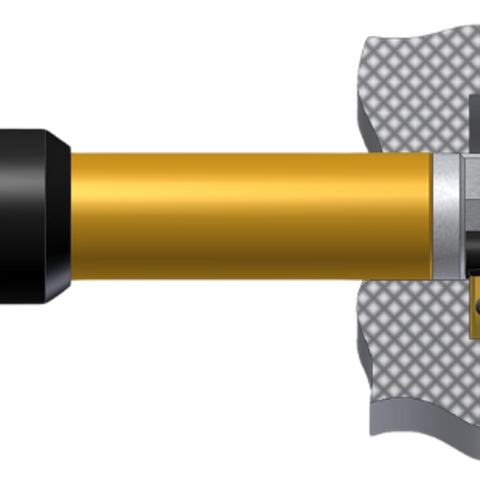

Applications

- Combined skive & burnish tools

- Range Ø60mm to Ø400mm

- Feed rates 3 to 6 mm/rev

- Finish tube bores in a single pass

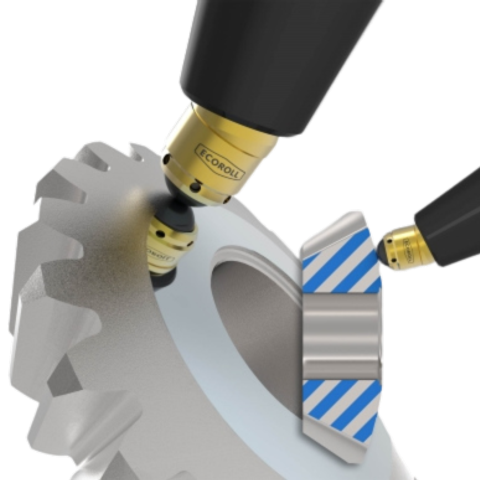

Applications

- For finishing OD surfaces and faces

- Suitable for materials to 65HRC

- Range of shanks available

- Achieve surface finishes to 0.1Ra

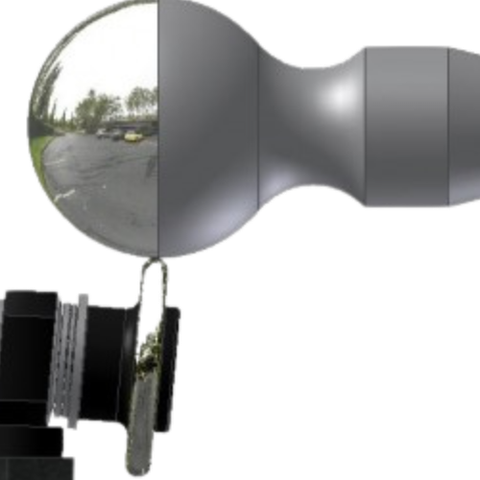

Applications

- Roller burnishing up to 65 HRC and deep rolling

- Increase fatigue strength for internal, external diameters and fillet radii

- Follow complex contours and free-form surfaces

- Range of ball sizes available

- Uses high-pressure oil or air