Roller Burnishing

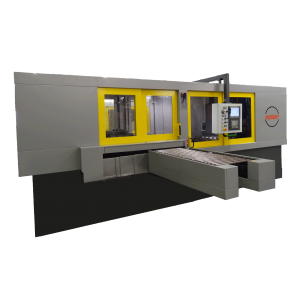

Mollart Roller Burnishing

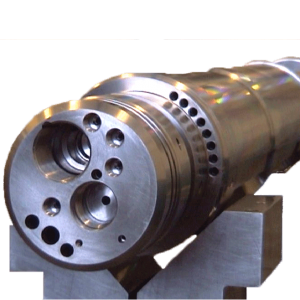

Mollart roller burnishing equipment provides chipless machining and cold working of surfaces to create high specification surface finishes, eliminating the grinding process.

Internal & external multi-roll tools along with carbide roll tools for ID and OD profiling of parts on CNC machines.

Mollart multi-burnishing tools are designed for burnishing shafts, faces tapers, contours, and IDs greater than 70mm.

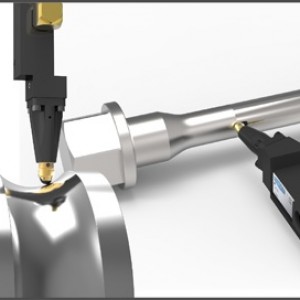

Ecoroll deep rolling and combined skive-burnishing tooling

Ecoroll roller burnishing, deep rolling and combined skive-burnishing tooling can be applied to blind or through bores, stepped bores as well as inner and outer surfaces. A heavy duty range of skiving heads is available for opening larger tube bores providing combined boring with burnished surfaces.

Applications

|

|

- Automotive

- Hydraulic & fluid power

- Aerospace

- Medical

- Construction

Our Range

Specifications

- Roller burnishing up to 65 HRC and deep rolling

- Increase fatigue strength for internal, external diameters and fillet radii

- Follow complex contours and free-form surfaces

- Range of ball sizes available

- Uses high pressure oil or air

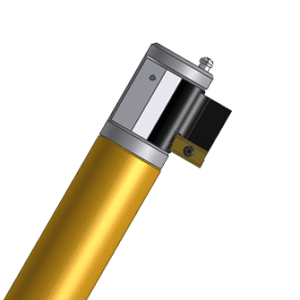

Specifications

- Tools for OD and ID profile burnishing

- Range of roll forms available

- Metric & imperial shanks

- Ideal for irregular surfaces, including specific contours, fillets and grooves as well as cylindrical and tapered external surfaces.

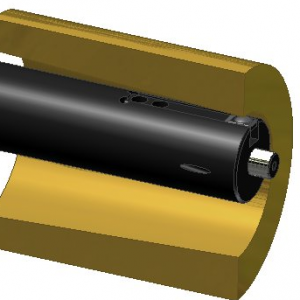

Specifications

- Combined skive & burnish tools

- Range Ø60mm to Ø400mm

- Feed rates 3 to 6 mm/rev

- Finish tube bores in a single pass

Specifications

- Suitable for bores and shafts

- Remove need for honing, grinding, fine boring

- Finishes down to 0.1Ra

- Improve surface hardness

Specifications

- For finishing OD surfaces and faces

- Suitable for materials to 65HRC

- Range of shanks available

- Achieve surface finishes to 0.1Ra