Combination Prismatic 3-4-5 and 6-Axis

Mollart has developed a series of 3, 4, 5 and 6-axis, single and dual spindle combination gundrill and CNC machining centres to provide single cycle, multi-feature machining incorporating deep hole drilling and conventional milling and drilling cycles.

Applications

|

|

Our Range

Specifications

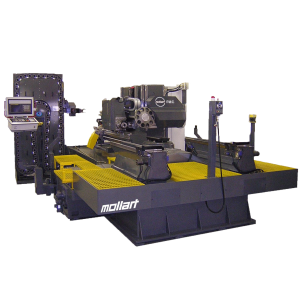

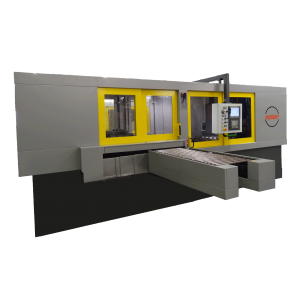

- 6-axis flexible machining centre

- Retractable whipguide, turret bush change and pallet changer

- Ø5mm to Ø50mm by 1,340mm deep

- Auto-tool change magazines including gundrills

- Column-type machine with crossfeed table

- 600mm pallet

Specifications

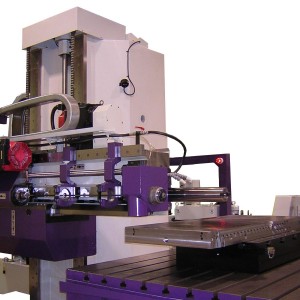

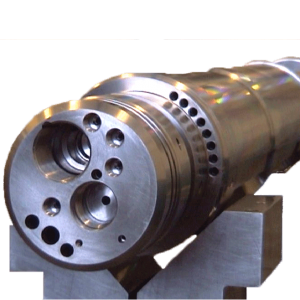

- Heavy duty ram-style, 6-axis

- 2 spindles

- Combined gundrilling with milling

- Ø5mm to Ø50mm x 2,000mm deep

- Suitbale for super alloys, titanium, Inconel

Specifications

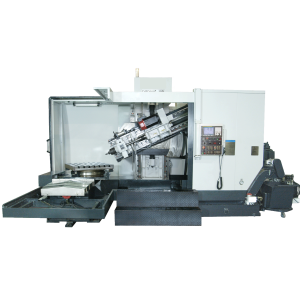

- Low cost 3 to 5-axis ram-type

- Ejector drilling, milling and drilling

- Gundrill Ø3 - Ø35mm x 1,500mm deep

- Tilting A-axis option

- Auxilliary Milling Spindle

- Table up to 15 tonne

- Guarded to CE standards

Specifications

- Column-type, 6-axis machine

- 2 spindles with 25º Tilting head

- Gundrill Ø5mm to Ø80mm x 2,000mm deep

- Rotary table 2,000 x 2,740mm

- Compound angle holes

- Auxiliary operations such as milling, threading and drilling

Specifications

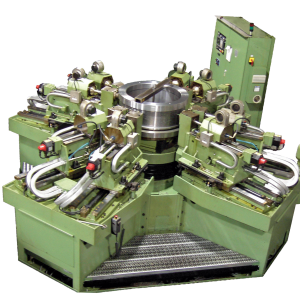

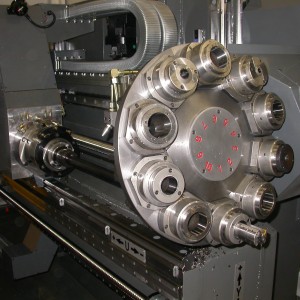

- Off-centre drilling

- 3, 4 or 5-axis machine options

- Ø2mm to Ø22mm drilling range

- Drilling depths to 1,000mm

- Fanuc CNC control with process monitoring