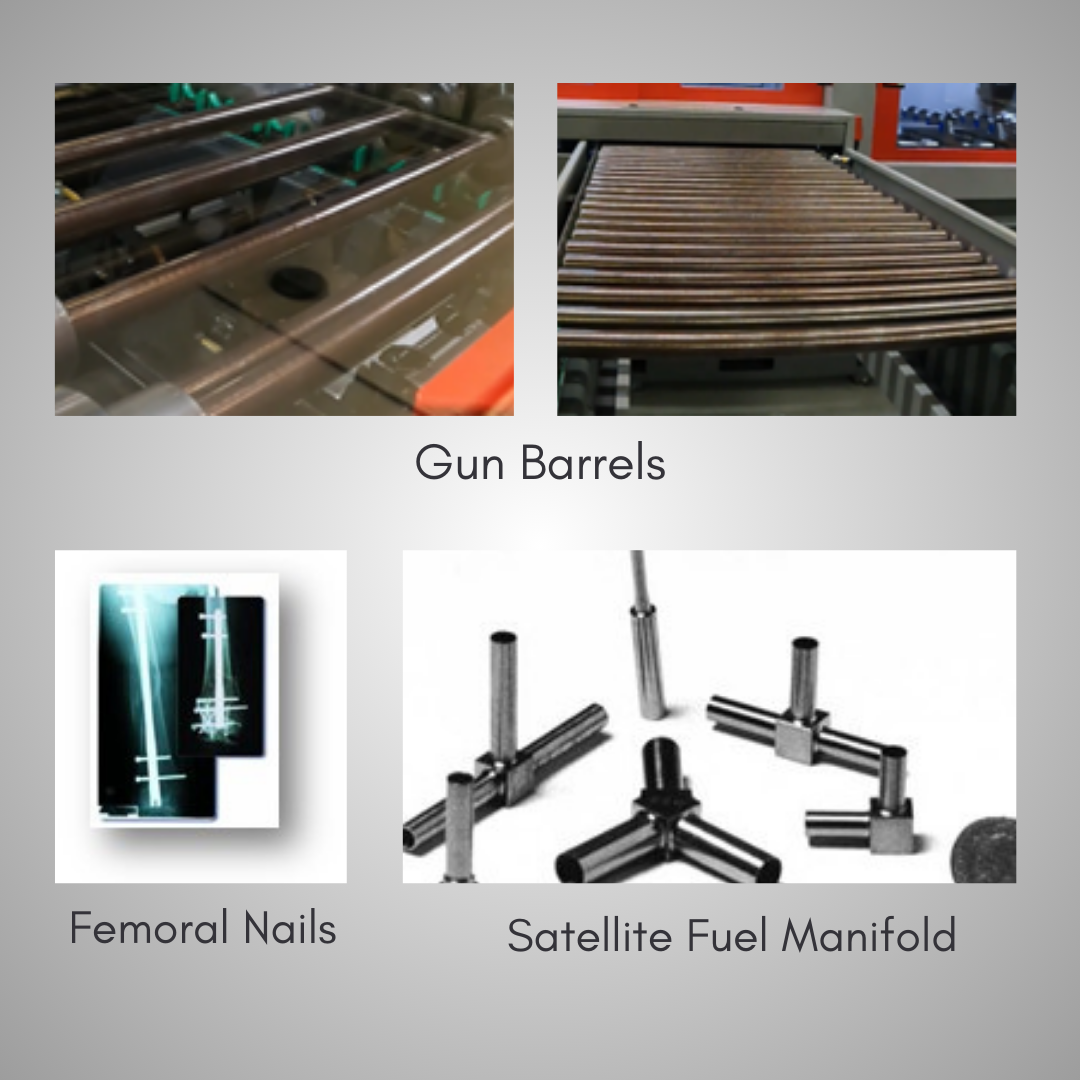

Mollart Drillsprint Series - With Standard and Customised Applications

The Drillsprint range of machines are available with Light or Medium duty capabilities to cover a wide range of deep hole drilling applications.

The machines can accommodate specifications and customised applications, with designs available to suit volume and individual specific needs. The full machine table feature provides additional flexibility for fixturing to enable offset hole drilling.

Auto loading options range from single belt to fully integrated robotic and gantry systems.

Fanuc Control Packages

With full Fanuc control packages, the machines can be developed easily to match the performance of the materials and tooling. Special machine cycles are now standard with these machines, so full ramp feed and speed are possible and can be applied on entry and exit of the product.

Typical applications:

1. Automotive & Transmission

-

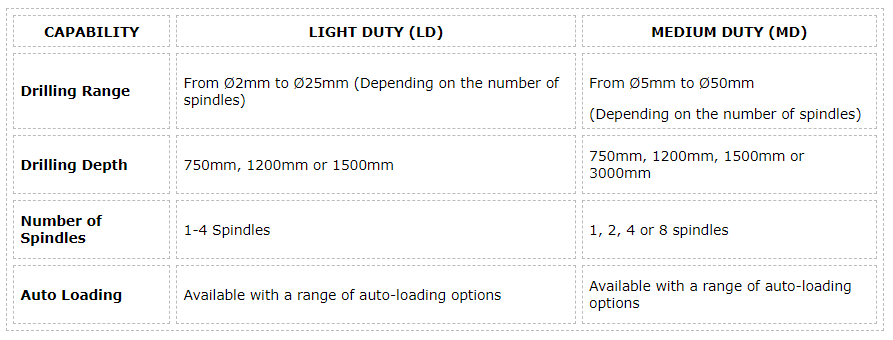

Gearbox shafts

Our special designed Light Duty Drillsprint can produce a range of automotive parts. Pictured above is a gearbox camshaft that has 3 holes in each part, with two different diameters 6mm & 7mm. The depth of hole is different for each one and is up to 384mm deep, with only 1.5mm land between the holes. We managed to maintain 0.2mm of the true position at a drilling depth of 200mm at a feed rate of 150mm per min in an alloy steel. The machine also includes industry 4.0 technology (Smart factory), which will increase productivity and safety.

-

Con-Rod

This is an automated Drillsprint Cell to produce Con-Rod oil holes for the automotive industry. Drilling the oil hole from Pin to Main and with a special fixture it is able to cover multiple variants. The machine was supplied with a pendulum loading system with two sets of fixtures that allowed for load and unload whilst still drilling the previous parts.

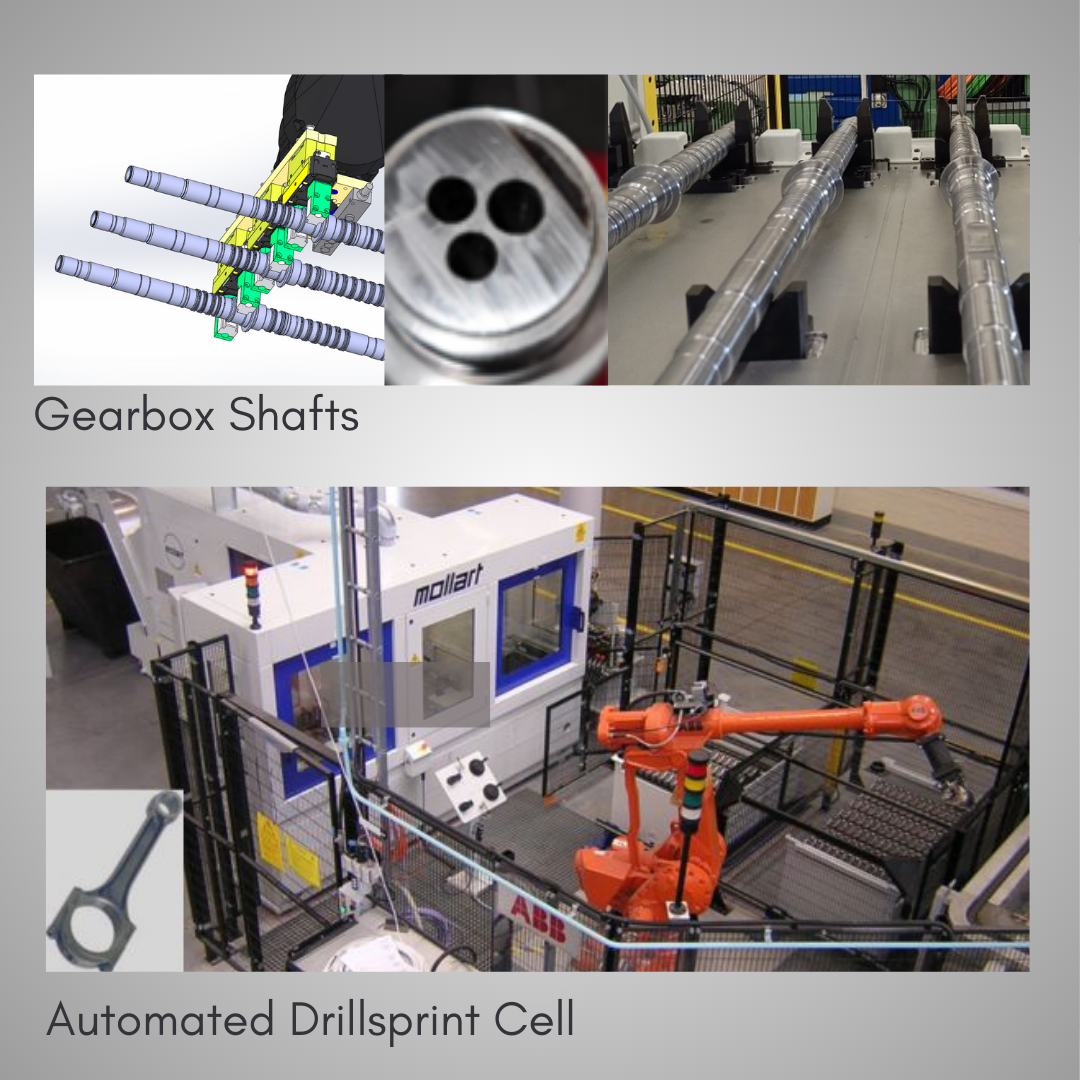

2. Medical

Femoral Nails

Femoral Nails are a bone support put into the bone after a major trauma. They can be made from stainless steel and various types of titanium based materials. These parts typically have a hole through in the region of 4.5- 5.0mm and need to be as close to being on the true centre as possible, to avoid weakening the material. Mollart’s special version Drillsprint is specifically designed to deal with this demanding application and can be provided in 1 – 3 spindle variants, with hydraulic or manual collet chucking to support the part. Plus special self-centering steadies to make sure the parts are as straight as possible prior to drilling.

Typical results over 500mm of drilling will be better than 0.1mm off-centre or 0.2mm TIR. Other methods of production can have a risk of having flaws in the wall where they have been drawn down to size. This method eliminates this risk completely.

3. Defence

Gun Barrels

When you need the best accuracy from your rifle, the most important part to look after is the barrel. Mollart has developed many tooling and machine attributes that allow our customers to drill the best quality with the least cost. This applies to Rim Fired rifles as well as high-powered air rifles, or even shotguns. For specialist companies we have delivered combination machines that can drill as well as pull ream. Talk to us about your specific needs and we will do our best to accommodate them. If you’re looking for automated drilling, reaming and rifling machinery, we can do it all with one-stop shop experience!

4. Aerospace

Satellite Fuel Manifold

Super light hydraulic fittings made from titanium are drilled in a special fixture to allow the parts to be drilled on our standard Drillsprint machine. The Drillsprint range is fitted as standard with a precision table with a centre tenon location, this enables fixtures to be mounted easily without major cost or time required.

Mollart Deep Hole Drilling Solutions

All of our machines are fitted with a full Fanuc control package, enabling you to control the process from start to finish. Specialist cycles have been developed to make the process as stable as possible so that ultimate production speeds can be achieved.

Due to the vast number of customers we have supplied over the years, we have a wealth of experience and will normally have a solution for all your deep hole drilling needs. You can find out more about Mollart manufactured Drillsprint machines here or get in touch at sales@mollart.co.uk to discuss your individual project. If you have a particular problem and need a solution, we always have someone on hand who can help.

For a free quote, covering any one of our business areas please get in touch here