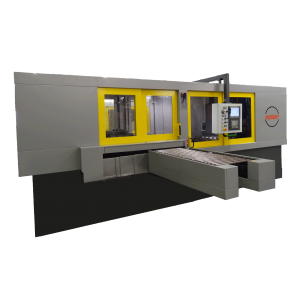

Mollart’s Latest Pull Reaming Machine (PR2-750) for Defence and Sporting Goods Industry

Mollart Engineering has designed and built an Automated Pull Reaming machine (PR2-750) which is capable of reaming from Ø2mm to Ø13mm using two spindles simultaneously with a standard reaming depth capacity of Ø750mm. The machine is fitted with a Fanuc CNC system and Mollart advanced software and is configured to work with a robot to load and unload the machine automatically. The Hydraulically clamping tailstock is manually adjustable for positioning and clamping along the worktable. This offers the setting capability for different length barrels.

Design & Effective Process

The specific goal of this machine was to design the machine so that the reaming process could be fully automatic. Other equipment mainly relies on the operator to remove the reamers and reload them for the next operation. Mollart designed the machine with a gantry system to deal with the movement of the reamers and also options such as auto door open so that the machine can be Robot fed and therefore save the customer money.

Alternative Options

-

Auto Threading Of Reamer

This option will allow the machine to take the reamer from the tailstock side of the machine and re- threads it through the component and couples it to the spindle ready for the next cycle. The option will include a pick and place gantry system, hydraulic tool clamping to ensure the spindles are loaded correctly, and the operation is safe to start.

-

Simple Programmable Robot Interface

We have added the Profibus master control card to the control system of the machine. This will allow the user to configure the handshake the robot requires to load and unload the machine successfully. Mollart also has experience of supplying the full robot package as well, but on this occasion, the customer wants to integrate the robot by themselves.

-

Automatic Door Opener/ Closer

An automatic door is fitted to the machine but can only be used while in Robot mode which will have a full safety fence installed by the customer. In a manually loaded condition, it can be configured so the door will auto-open which is in compliance with the latest CE standards.

Defence Project

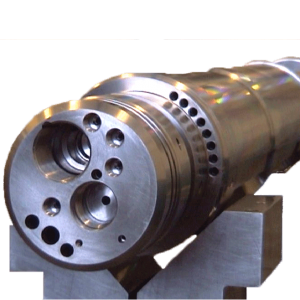

Pictured below is a two-spindle machine that has a 750 pull reaming length capacity, with a diameter range of Ø2mm to Ø13mm. The machine is going to a customer in the Defence industry who intends to use the Mollart machine to manufacture gun barrels, where the accuracy of the reaming surface finish of parts is fundamental. We achieved a bore diameter consistent at 7.556mm with a typical surface finish of 0.12mm Ra – 0.28 Ra over 700mm depth in carbon steel.

If you would like to know more about this machine or other deep hole drilling machines at Mollart please contact us. For general information take a look at our other machinery