History

Mollart Engineering was originally setup in 1929 by the previous managing director’s grandfather Arthur Mollart and partner J Hendra as a production engineering source of components for the car and aircraft industries. Through the following years Chessington, Surrey based Mollart Engineering has benefitted from boom years and survived multiple UK and world recessions to achieve a record year in 2015 and continues to invest in its future growth and development. In March 2016 there was a management buy-out with the 5 existing directors taking on the running of the business.

|

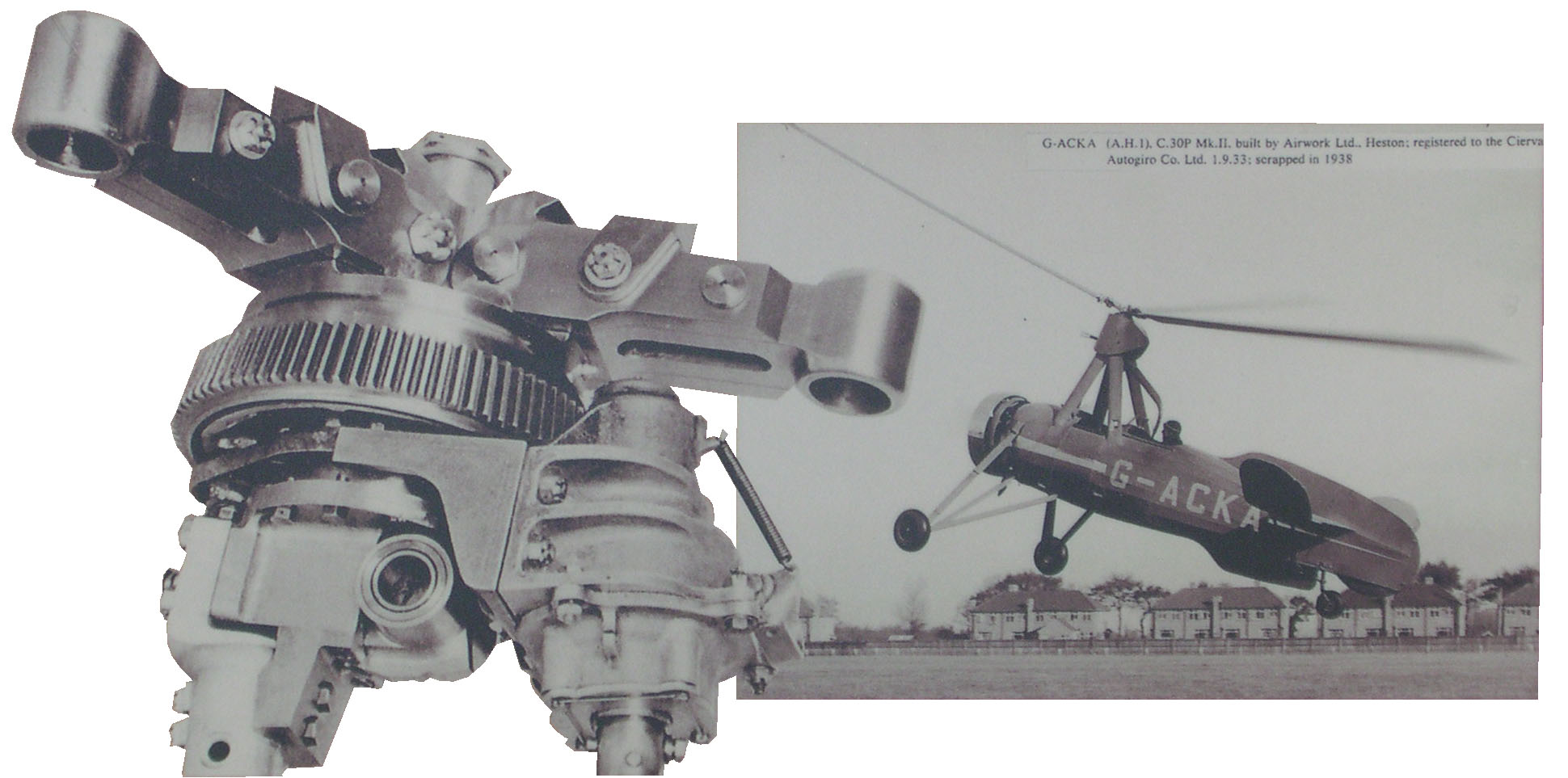

1933 |

Involved in the development of Autogiros producing the main rotor head. |

|

| 1939- 45 |

Specialised in fixturing, gauging, and production of universal joints. Produced arrester hooks for Fairey Swordfish aircraft and mechanical computer for Bofors AA gun predictor |

|

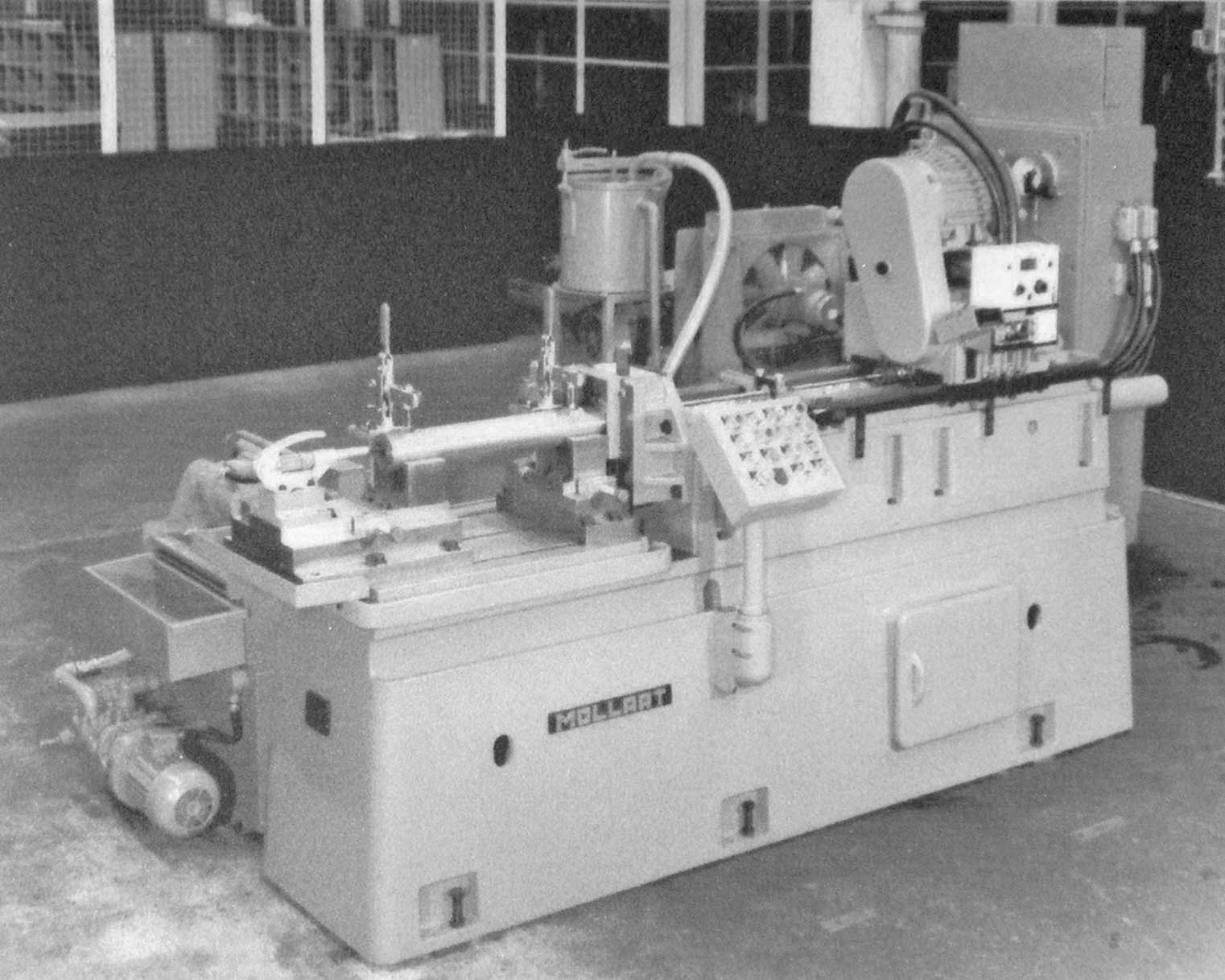

| 1965 |

Developed its first gundrilling machine. |

|

| 1983 |

Guy Mollart appointed as Managing Director. |

|

| 1993 |

Started manufacture of Botek gundrills under licence in the UK. |

|

| 1997 |

Set up subcontract production of power steering racks in new Resolven facility in South Wales. |

|

| 2001 |

Manufactured its first Microdrilling machine for the automotive fuel injection and medical markets. |

|

| 2002 |

Invested £1 million in production machinery at Resolven to establish Mazak Integrex multi-axis and 5-axis machining capability. |

|

| 2008 |

Acquired Bencere tooling company which offers roller burnishing, back spot facing and hole deburring tools. |

|

| 2011 |

Obtained grants to develop Accubore steerable gundrill technology and abrasive flow deburring. |

|

| 2013 |

After winning its 40th order Mollart established as biggest overseas supplier of gundrill machinery to China. Invested in the Chessington factory and office extension. Also increased machining capability. |

|

| 2014 |

Invested almost £2 million in new production, fabrication and ISO7 cleanroom assembly area. |

|

| 2015 |

Wins £4.8 million fuel injection gundrill machine order.

Becomes world leader in special purpose pellet die drilling machine supplier with 450 gundrilling spindles installed.

Wins its biggest ever £5 million North American machine order for gundrilling gearbox components.

Record sales lift turnover to £20 million and employees to 150.

Guy Mollart appointed President of Manufacturing Technologies Association (MTA) which has over 300 members made up from machine tool builders, tooling suppliers, manufacturing software and subcontract manufacturers.

Gundrill installations in China reach 60 machines.

Resolven facility has a 12,000 sq foot extension added to cope with the increased demand for sub-contract machined parts. |

|

| 2016 |

Guy Mollart retires and the 5 existing directors take over the business as part of a management buy-out with Vine Street Capital support.

|

|

| 2017 - 2019 |

Launched new machines 2017: Developed new VDMF machine. The machine was upgraded to the latest Fanuc control system. 2018: Produced 4-spindle Omnisprint machine, which has increased drill feed for mold manufacturer by 500%. 2018: Produced a true BTA machine capable of up to 50mm drilling in exotic materials and gundrilling down to 5mm.

|

|

| 2020 |

Continued to invest on product design and development for the most complex bespoke productions. |

|

| 2021 |

Increased capacity: ISO6 cleanroom extension at Resolven site. |

|

| 2022 |

Machine development: Produced high performance Drillsprint Series with robot cells. The machine cell includes industry 4.0 technology (smart factory) which will increase productivity and reduce production cost. |

|

| 2023 |

The Mollart Machine tools business which trades through the entity Mollart Engineering Limited has been acquired by InCompass™ (an American based company) in August 2023. The sale of this business does not include our world-class subcontract machining and assembly, deep hole drilling and tooling businesses, which reside at our facilities in Chessington and Resolven in the UK. |