IRU Grooving

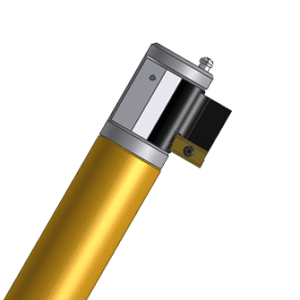

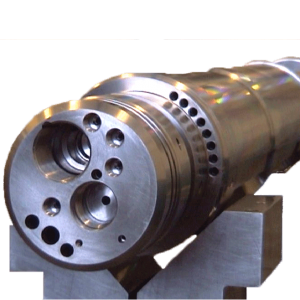

The Bencere “IRU” recessing system is the most efficient method of machining single or multiple internal grooves in one operation. The system comprises of an operating head, location pilot, carrier arm and cutter.

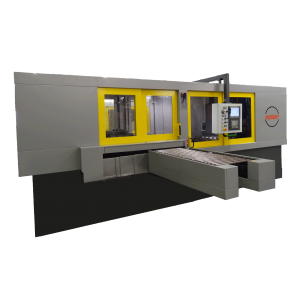

The grooving system is ideally suited for the manufacture of land metering faces within hydraulic and pneumatic bores.

Conventional cycle times by interpolation can be reduced to less than 1 minute using the IRU system offering massive time and cost savings.

The design of the IRU system ensures the cutter is supported along its entire length by the pilot. This eliminates deflection and ensures precise feature machining.

Cycle times can be reduced from hours to minutes over conventional techniques offering massive cost reductions while maintaining critical dimensional accuracies.

Want the most efficient method of machine single or multiple grooves? The IRU recessing system, is the best choice!