Mollart Chessington Secures Major Defence Contract

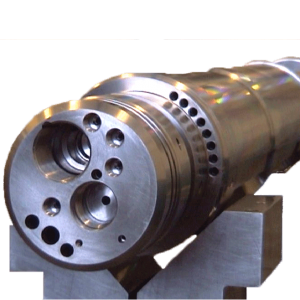

WE ARE PLEASED TO HAVE WON A MAJOR CONTRACT TO DEEP HOLE DRILL A COMPONENT FOR THE DEFENCE SECTOR, WHICH WAS FIRST MANUFACTURED OVER TWENTY-FIVE YEARS AGO!

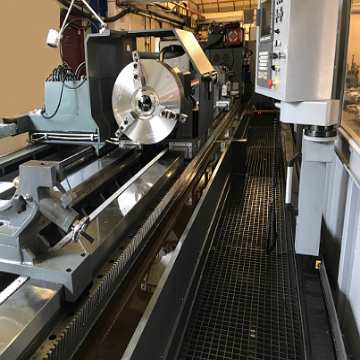

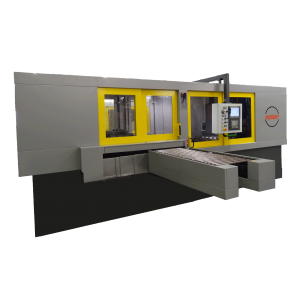

Utilizing our recently commissioned HD1 deep hole BTA machine, we were able to stand apart from all our competitors. This was due to the unparalleled support from our in-house tooling partner BOTEK, who in collaboration with our experienced subcontract team, came up with a modern and efficient solution to a very old machining/tooling challenge.

The Challenge:

-

Drill Ø97.00mm through bore X 600mm deep in an irregular profiled component.

-

Forged material, extremely challenging to procure.

-

No allowance for a second chance.

The Solution:

-

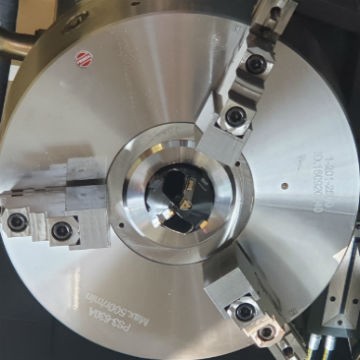

BOTEK type 42 drilling head utilizing special coated inserts.

-

In house designed and manufactured bushing technology.

-

In house designed and manufactured work holding.

Deep Hole Drilling Versatility

The successful drilling of this component has proved Mollart can drill holes in any shaped component by utilizing the versatility of the HD1, which has a working envelope of drilling Ø150mm solid in material with KSI values up to 140, counterbore up to Ø250mm, all up to 3mtrs deep while encompassing an overall work piece diameter of 700mm.

Mollart Chessington is open to all your large deep hole drilling requirements and look forward to assisting in its associated challenges.

If you would like further information about the HD1 capabilities or to discuss a project please either send an enquiry, or get in touch here