Oil and Gas

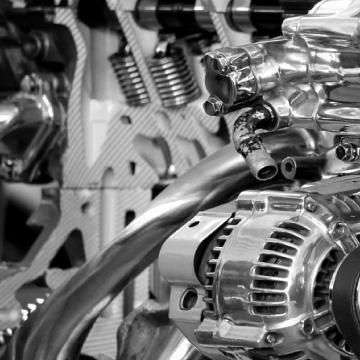

At Mollart Engineering we offer comprehensive machining services to the Oil and Gas industry. With an emphasis on research and investment, we have been able to gain the skills, knowledge and machining capabilities to be able to meet the stringent and distinct technological requirements of the oil and gas industry.

We are experts in working with corrosive resistant, high temperature alloys and producing precision designed parts that will withstand testing environments. Our exceptional industry experience enables us to not only be at the forefront of industry developments but to also produce parts that are made to the highest standards and quality. We can produce components that many other companies would not even consider due to our internally developed processes and technology that allow us to achieve superior tolerances and quality than many of our competitors.

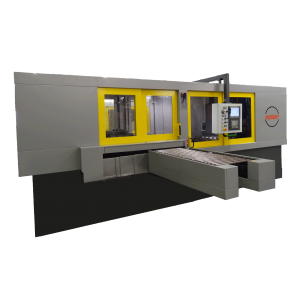

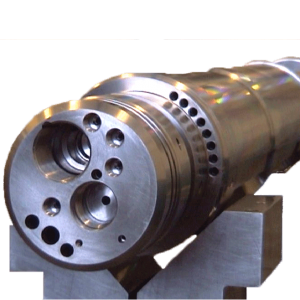

Our machining centres have the capacity to produce components up to 3000mm (118”) in length in materials such as Inconel, Titanium plus a wide range of stainless steels and other exotic materials. Typical components we machine for customers include directional drilling equipment, down-hole casings, equipment chassis, manifolds and other products associated with the oil exploration and production process.

CNC gundrilling and BTA drilling, reaming, counter boring and trepanning of close tolerance holes is a core skill within Mollart. We have the capability to drill holes from Ø0.5mm (Ø0.020”) to Ø200mm (Ø7.87”) on-centre, off-centre and at angles, with the emphasis on producing a quality product in a timely manner.