Centeplex

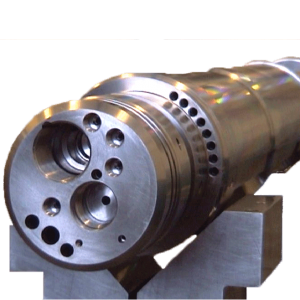

The Centeplex 6-axis combination deep hole drilling machine and conventional machining centre is able to produce deep holes Ø5mm to Ø80mm by up to 2,000 mm in depth while having the capability to perform milling, drilling, boring and threading from an under/over shotgun style secondary spindle.

The spindle arrangement has an in-cycle CNC capability to tilt up to 25° to produce compound angles.

Spindle power is 22 kW and has an ISO50 taper with fully automatic tool changing capability.

The full CNC rotary table size is 2,000mm x 2,740mm and has a maximum weight capacity of 16 tonnes.

Ideally suited for machining of moulds, heat exchanger plates, hydraulic manifolds, cylinders for rolling mills, oil and gas and aerospace components.

- Column-type, 6-axis machine

- 2 spindles with 25º Tilting head

- Gundrill Ø5mm to Ø80mm x 2,000mm deep

- Rotary table 2,000 x 2,740mm

- Compound angle holes

- Auxiliary operations such as milling, threading and drilling

Our Range

Specifications

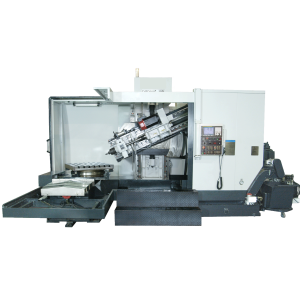

- 6-axis flexible machining centre

- Retractable whipguide, turret bush change and pallet changer

- Ø5mm to Ø50mm by 1,340mm deep

- Auto-tool change magazines including gundrills

- Column-type machine with crossfeed table

- 600mm pallet

Specifications

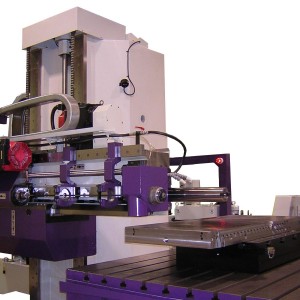

- Off-centre drilling

- 3, 4 or 5-axis machine options

- Ø2mm to Ø22mm drilling range

- Drilling depths to 1,000mm

- Fanuc CNC control with process monitoring

Specifications

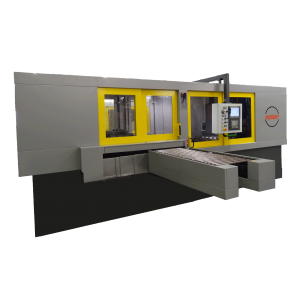

- Low cost 3 to 5-axis ram-type

- Ejector drilling, milling and drilling

- Gundrill Ø3 - Ø35mm x 1,500mm deep

- Tilting A-axis option

- Auxilliary Milling Spindle

- Table up to 15 tonne

- Guarded to CE standards

Specifications

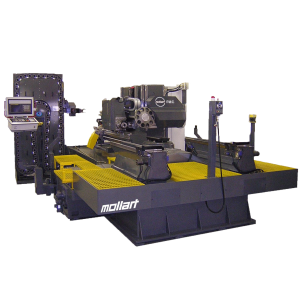

- Heavy duty ram-style, 6-axis

- 2 spindles

- Combined gundrilling with milling

- Ø5mm to Ø50mm x 2,000mm deep

- Suitbale for super alloys, titanium, Inconel